Product

BALL VALVE INTRODUCTION

Ball valve are widely used in petroleum refining, long-distance pipeline, chemical, paper, electric power, iron and steel industry on the device, the specific device are: coal gasification device, catalytic cracking device, catalytic reforming device, delayed coking device, hydrocracking device, hydrogenation refining device, gas air separation device.

The materials of ball valve are: A105, LF2, F304L, duplex stainless steel, Inconel, Hastelloy, ceramics and so on.

Ball valve have full bore, large flow, low flow resistance, easy to switch, etc., in the pipeline is mainly used to do cut off, adjust, distribute and change the direction of flow of the medium.

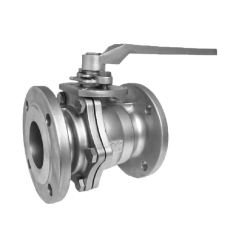

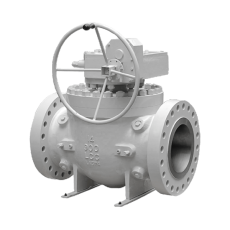

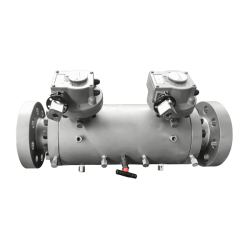

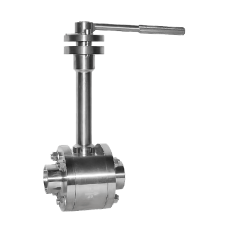

Common types of ball valves: floating ball valves, fixed stainless steel ball valves, V-shaped stainless steel ball valves, orbital ball valves and so on.

Advantages

Ball valve are widely used because of their fast switching, good sealing and multifunctional characteristics, but users need to choose the right ball valve model according to specific application scenarios and needs.

Small fluid resistance

Due to its internal flow path is spherical, the ball valve has a small fluid resistance.

Fast switching

Ball valve are easy to operate, the opening and closing process is rapid, only need to rotate 90 degrees to achieve full open or full closed.

Good sealing

Ball valve usually use elastic material as the valve seat, with good sealing performance.

Applicable to a variety of fluids

The structure of the ball valve is simple, easy to maintain, and can be applied to a variety of fluid control occasions.

strong corrosion resistance

Ball valve material variety, including rubber, PTFE and metal ring and other types, to adapt to the use of different media environment.

Multi-purpose

Ball valve can be used for cut-off and fully open and closed control occasions, but also can be used to regulate the flow control.

And the design of the ball valve allows it to work properly at higher temperatures and pressures.

selection instructions

Ball valves are suitable for low temperature, high pressure, viscosity of the medium.

Most ball valves can be used in the medium with suspended solid particles, according to the requirements of the sealing material can also be used for powdery and granular media.

Full-channel ball valve are not suitable for flow regulation, but for the requirements of rapid opening and closing of the occasion, to facilitate the realization of the emergency cut-off accident.

Usually in the strict sealing performance, wear and tear, indented channel, open and close quickly, high pressure cut-off (differential pressure), low noise, gasification phenomenon, operating torque is small, small fluid resistance pipeline, the recommended use of ball valves.

Ball valves are suitable for lightweight structure, low pressure cut-off, corrosive media.

Ball valve or low temperature, deep cold media, the most ideal valve, low-temperature media piping systems and installations, it is appropriate to choose to add the bonnet of the low-temperature ball valve.

Selection of floating ball valve seat material should undertake the ball and the load of the working medium, large caliber ball valves require greater force during operation, DN ≥ 200mm ball valve should be selected worm gear transmission form.

Fixed ball valve are suitable for larger caliber and higher pressure occasions.

In addition, the ball valve used for process highly toxic materials, combustible media pipeline, should have fire prevention, anti-static structure.

How to choose valve?

Classification of

valves

Valves can be divided into two general categories

The first category of automatic valves: rely on the medium (liquid, gas) the ability to act on its own valves.

Such as check valves, safety valves, control valves, traps, pressure reducing valves.

The second type of drive valve: with the help of manual, electric, hydraulic, pneumatic to manipulate the action of the valve.

Such as gate valves, globe valves, throttle valves, butterfly valves, ball valves, plug valves and so on.

It can be divided by structural features

1. gate shape: the closing member moves along the center of the valve seat;

2. Gate: the closing member moves along the center of the vertical valve seat;

3. Plunger and ball: the closing member is a plunger or ball, rotating around its own centerline;

4. Spin-open shape: the closing member rotates around the axis outside the valve seat;

5. disc-shaped: the closing member of the disk, around the valve seat within the axis of rotation;

6. slide valve shape: the closing member slides in the direction perpendicular to the channel.

Depending on the use of the valve

1. open and close: used to connect or cut off the pipeline medium, such as globe valves, gate valves, ball valves, butterfly valves and so on.

2. Check: used to prevent the medium backflow, such as check valves.

3. Adjustment: used to adjust the pressure and flow of the medium, such as regulating valves, pressure reducing valves.

4. Distribution: used to change the direction of flow of media, distribution of media, such as three-way plug, distribution valves, slide valves.

5. Safety valve: in the medium pressure exceeds the specified value, used to discharge excess media, to ensure the safety of piping systems and equipment, such as safety valves, accident valves.

6. Other special purposes: such as traps, vent valves, sewage valves, and so on.

Depending on the type of drive

1. Manual: with the help of handwheel, handle, lever or sprocket, etc., there are manpower drive, transmission of large torque is equipped with worm gears, gears and other deceleration devices.

2. Electric: with the help of motor or other electrical devices to drive.

3. Hydraulic: with the help of (water, oil) to drive.

4. Pneumatic: driven by compressed air.

According to the nominal pressure of the valve

1. Vacuum valve: Absolute pressure <0.1Mpa, that is, 760mm Hg high valve, usually with mm Hg or mm water column pressure.

2. Low-pressure valve: nominal pressure PN ≤ 1.6Mpa valve (including PN ≤ 1.6MPa steel valve)

3. Medium-pressure valve: nominal pressure PN2.5-6.4MPa valves.

4. High-pressure valve: nominal pressure PN10.0-80.0MPa valve.

5. ultra-high pressure valve: nominal pressure PN ≥ 100.0MPa valve.

According to the valve operating medium temperature

1. Ordinary valves: valves suitable for medium temperature -40 ℃ ~ 425 ℃.

2. High-temperature valves: for medium temperature 425 ℃ ~ 600 ℃ valve.

3. Heat-resistant valves: for media temperature 600 ℃ or more valves.

4. Low-temperature valves: for media temperature -150 ℃ ~ -40 ℃ of the valve.

5. Ultra-low-temperature valves: for media temperature -150 ℃ below the valve.

According to the nominal diameter of the valve

1. Small diameter valves: nominal diameter DN <40mm valve.

2. Medium caliber valves: nominal diameter DN50 ~ 300mm valve.

3. Large caliber valves: nominal diameter DN350 ~ 1200mm valve.

4. Very large caliber valves: nominal diameter DN ≥ 1400mm valve.

According to the way the valve is connected to the pipeline

1. Flange connection valve: valve body with a flange, and the pipeline using a flange connection valve.

2. Threaded valves: valve body with internal or external threads, and the pipeline using threaded connections of the valve.

3. Welding connection valve: valve body with weld, and the pipeline using welding connection valve.

4. Clamp connection valve: valve body with clamp port, and the pipeline using clamp connection valve.

5. ferrule connection valve: the use of ferrule and pipe connection valve.

Steps and bases for

selecting valves

Steps for selecting valves

1. a clear valve in the equipment or device use, determine the working conditions of the valve: applicable media, operating pressure, operating temperature and so on.

2. to determine the nominal diameter of the pipeline connected to the valve and connection: flange, threaded, welded, etc..

3. to determine the mode of operation of the valve: manual, electric, electromagnetic, pneumatic or hydraulic, electrical linkage or electro-hydraulic linkage.

4. according to the pipeline medium, working pressure, working temperature to determine the selected valve shell and the inner parts of the material: gray cast iron, malleable cast iron, ductile iron, carbon steel, alloy steel, stainless acid-resistant steel, copper alloy, etc..

5. select the type of valve: closed-circuit valves, regulating valves, safety valves and so on.

6. to determine the type of valve: gate valves, globe valves, ball valves, butterfly valves, throttle valves, safety valves, pressure reducing valves, steam traps and so on.

7. to determine the parameters of the valve: for automatic valves, according to the different needs of the first to determine the permissible flow resistance, discharge capacity, back pressure, etc., and then determine the nominal diameter of the pipeline and the diameter of the valve seat hole.

8. to determine the geometric parameters of the selected valve: structural length, flange connection form and size, open and close the valve after the height direction of the size, connecting the size and number of bolt holes, the entire valve dimensions.

9. the use of existing information: valve catalogs, valve product samples and other selection of appropriate valve products.

Basis for selecting valves

1. The purpose of the selected valve, the use of working conditions and manipulation and control methods.

2. the nature of the working medium: working pressure, working temperature, corrosive properties, whether it contains solid particles, whether the medium is toxic, whether it is flammable, explosive media, the viscosity of the medium and so on.

3. the requirements of the valve fluid characteristics: flow resistance, discharge capacity, flow characteristics, sealing grade and so on.

4. installation size and size requirements: nominal diameter, connection with the pipeline and connection size, dimensions or weight limitations.

5. additional requirements on the reliability of the valve products, service life and explosion-proof performance of electric devices.

Considerations when selecting parameters

If the valve is to be used for control purposes, the following additional parameters must be determined: the method of operation, the maximum and minimum flow requirements, the normal flow of pressure drop, the pressure drop at the time of closure, the maximum and minimum inlet pressure of the valve.

According to the above basis for selecting the valve and steps, reasonable and correct selection of the valve must also be a detailed understanding of the internal structure of various types of valves, so that the valve can be prioritized to make the right choice.

The final control of the pipeline is the valve. Valve opening and closing parts of the control of the medium in the pipeline beam way, the shape of the valve flow path so that the valve has a certain flow characteristics, in the selection of piping system is most suitable for the installation of the valve must take this into account.

Selection of valves

should follow the principle

Valves for shutoff and open medium

The flow path is straight through the valve, its flow resistance is small, usually selected as a cut-off and open medium with the valve.

Downward closing type valve (globe valve, piston valve) because of its flow path is tortuous, flow resistance is higher than other valves, so less selection.

In allowing a higher flow resistance of the occasion, can choose to close the valve.

Valves for flow control

Valves that are easy to regulate flow are usually selected for flow control. Downward closing type valves (e.g., globe valves) are suitable for this purpose because there is a proportional relationship between the size of the valve seat and the travel of the closing member.

Rotary valves (plug valves, butterfly valves, ball valves) and flexure body type valves (clamp valves, diaphragm valves) can also be used for throttling control, but are usually only applicable within a limited range of valve sizes. Gate valve is a disc-shaped gate to the circular valve seat mouth to do cross-cutting movement, it is only close to the closed position, can better control the flow, so usually not used for flow control.

Valves for reversing and diverting

These valves can have three or more passages, depending on the need for reversing and diverting flow.

Plug valves and ball valves are better suited for this purpose, and therefore one of these types of valves is selected for most of the valves used for reversing and diverting flow.

However, in some cases, other types of valves, as long as two or more valves are properly interconnected, can also be used for commutation.

Valves for media with suspended particles

When there are suspended particles in the medium, valves are best suited for use where the sliding of the closing member along the sealing surface has a wiping effect.

If the closing member of the valve seat back and forth movement is vertical, then the particles may be entrapped, so this valve unless the sealing surface material can be allowed to embed particles, otherwise only suitable for basic clean media.

Ball valves and plug valves in the opening and closing process of the sealing surface are wiping effect, so it is suitable for use in the medium with suspended particles.

Valve Application Fields

Oil & Gas

After natural gas is captured, it needs to be liquefied and then easily stored and transported. LNG import and export trade is generally carried by ship, and then arrives at a receiving station where it is re-gasified. The gasified natural gas is then transported through pipelines to the city pipeline network to each household.

Natural gas is collected and then requires a series of purifications. The natural gas is pre-treated to remove heavy hydrocarbons, sulphides, CO2, water and other impurities, and then liquefied by cooling it down to -160 degrees Celsius at room temperature.

All the gas and liquid extraction, transportation, storage will be used to cryogenic ball valves, usually pipeline selection will be used cryogenic disconnecting valve, cryogenic gate valve, cryogenic ball valves, cryogenic butterfly valves and so on.

Coal chemical industry

Coal chemical industry refers to the process of taking coal as raw material and converting coal into gas, liquid and solid fuels and chemicals through chemical processing. Mainly includes coal gasification, liquefaction, dry distillation, as well as tar processing and calcium carbide acetylene chemical industry.

Coal chemical industry mainly includes coal gasification, liquefaction, dry distillation, as well as tar processing and calcium carbide acetylene chemical industry.

Among the production technologies available for coal chemistry, coking was the earliest process to be applied and remains an important part of the chemical industry today. Syngas produced by coal gasification is the raw material for the synthesis of a wide range of products such as liquid fuels and chemical raw materials. Coal direct liquefaction, i.e., high-pressure hydro-liquefaction of coal, allows the production of man-made oils and chemical products.

The pump and valve equipment involved are valves, gate valves, globe valves, cryogenic ball valves, butterfly valves and so on.

Pharmaceutical & Fertilizer

Pharmaceutical industry is an important part of China’s national economy, is a combination of traditional and modern industries, primary, secondary and tertiary industries as a whole.

Its main categories include: chemical raw materials and preparations, Chinese herbal medicines, Chinese medicinal tablets, proprietary Chinese medicines, antibiotics, biological products, biochemical drugs, radiopharmaceuticals, medical devices, sanitary materials, pharmaceutical machinery, pharmaceutical packaging materials and pharmaceutical business. Common chemical pharmaceutical processes such as amino acid drugs, peptides and protein drugs, nucleic acids, enzymes, sugar drugs, lipids, vitamins and coenzymes, steroid hormone drugs and genetically engineered Pseudomonas pseudomonas production of interferon, etc., commonly used pharmaceutical equipment acidification equipment such as acidification tanks, sludge concentrators, reaction equipment such as reactors, distillers, etc., purification equipment such as stripping towers, furnaces, etc., drying processes such as mixers, vacuum equipment, drying process, pharmaceutical machinery, pharmaceutical packaging materials and business.

Drying process has a mixer, vacuum dryer, etc., pumps and valves have rotary check valves, gate valves, ball valves, safety valves, butterfly valves, electric globe valves electric safety valves.

Metallurgical mining

Mineral extraction refers to the extraction of naturally occurring minerals such as solids (e.g. coal and minerals), liquids (e.g. crude oil), or gases (e.g. natural gas). It includes underground or above-ground extraction, the operation of mines, and all ancillary work generally carried out at or near the mine site for the purpose of processing the raw materials, such as grinding, beneficiation and treatment, as activities in this category.

It also includes the preparatory work necessary to enable the raw materials to be marketed. It does not include the impoundment, purification and distribution of water, as well as geological exploration, construction and engineering activities, important ways in which mankind acquires important resources.

The ore mining process routinely has four processes: crushing, screening, smelting, and grinding. The process equipment involved are jaw crusher, crusher, fabric screening machine, cylinder dryer, mixer, quantitative belt feeder, aggregate tape machine, powerful mixing valve gate has gate valve, air release valve, water pump, screw pump, lifting pump, high-pressure pumps, three-way valve, high-pressure shut-off valve, butterfly valve and so on.

Light industry

Light industry using agricultural products as raw materials refers to light industry that uses agricultural products directly or indirectly as basic raw materials.

It mainly includes food manufacturing, beverage manufacturing, tobacco processing, textile, sewing, leather and fur production, papermaking and printing industries; light industry with non-agricultural products as raw materials refers to light industry with industrial products as raw materials.

It mainly includes industries such as stationery and sporting goods, chemical and drug manufacturing, synthetic fiber manufacturing, daily-use chemical products, daily-use glass products, daily-use metal products, hand tool manufacturing, medical equipment manufacturing, and machinery manufacturing for culture and office use; it covers 18 major categories of industries. Pump and valve products include gate valves, ball valves, safety valves, butterfly valves and so on.

Environmental Protection Project

Environmental protection engineering refers to the works done specifically for the purpose of environmental protection, which is the treatment of solid, gas and liquid pollution in cities. Sewage and garbage treatment are widely used in various fields such as construction, agriculture, transportation, energy, petrochemical, environmental protection, urban landscape, medical treatment and catering.

Urban wastewater treatment process should be based on the scale of treatment, water quality characteristics, the environmental function of the receiving water body and the actual situation and requirements of the local community, after a comprehensive technical and economic comparison of preferential determination.

Modern sewage treatment technology, according to the degree of treatment, can be divided into primary, secondary and tertiary treatment. Primary treatment, the main removal of sewage in a suspended state of solid pollutants, most of the physical treatment method can only complete the requirements of primary treatment. Secondary treatment, the main removal of sewage in the colloidal and dissolved state of organic pollutants (BOD, COD substances), the removal rate of up to 90% or more, so that organic pollutants to meet the discharge standards. Tertiary treatment, further treatment of difficult to degrade organic matter, nitrogen and phosphorus can lead to eutrophication of the water body, such as soluble inorganic substances. The main methods are biological nitrogen and phosphorus removal, coagulation and precipitation, sand filtration, activated carbon adsorption, ion exchange and electro-osmosis analysis.

Common wastewater treatment technologies are the separation of insoluble pollutants, the biochemical transformation of pollutants, the chemical transformation of pollutants, the physical and chemical separation of dissolved pollutants.

Commonly used pumps and valves are, gate valves, electric gates, steel gates, plug gates, pneumatic switches, butterfly valves, check valves, globe valves, traps, venting valves, throttle valves, ball valves and so on.

Electric power engineering

Electric power plant according to the type of energy is divided into thermal power plant, hydropower power plant, nuclear power plant and other energy generation power plant.

Thermal power plant by the boiler, turbine and generator (customarily known as the three main engine) and its auxiliary devices, by the combustion system (boiler as the core), steam system (mainly by various types of pumps, feedwater heaters, condensers, piping, water-cooled wall, etc.), the electrical system (turbine generator, main transformer, etc.), control systems and other components. The first two produce high-temperature and high-pressure steam; the electrical system realizes the transformation from thermal and mechanical energy to electric energy.

Hydroelectric power plant consists of hydroelectric generator set, governor, oil pressure device and other auxiliary devices, the use of water potential energy into the mechanical energy of the water wheel, and then mechanical energy to promote the generator, and get electricity. Nuclear power plant by the nuclear reactor, steam generator, turbine generator set and other ancillary equipment, nuclear reactor according to the neutron energy caused by fission is divided into thermal neutron reactors and fast neutron reactors.

The pump and valve equipment involved are gate valves, ball valves, safety valves, butterfly valves and so on.

Water Conservancy Engineering

Water conservancy engineering water resources, urban water, water engineering, ecological hydrology, harbor coast and offshore engineering, agricultural water conservancy.

Large to the national project South-to-North Water Diversion, small to the people’s livelihood drinking, and the country and individuals are closely related. Wherever water conservancy, pipeline first.

Pumps and valves are indispensable, water-related pumps and valves are axial flow pumps, centrifugal pumps, vacuum pumps, sewage pumps, water supply pumps, water pumps, submersible pumps, sluice gates, cast iron gates, plane sliding gates, exhaust valves, pressure-reducing valves, butterfly valves, curved steel gates, air valves, check valves, ball valves, gate valves and so on.