Trunnion mounted ball valve

Trunnion Mounted Ball Valve

Trunnion mounted ball valve is a new generation of high-performance ball valves, suitable for long-distance pipeline and general industrial pipelines, its strength, safety, resistance to harsh environments, etc.

In the design of special considerations, applicable to a variety of corrosive and non-corrosive media.

Product information

1. Operating: Extended lever for easy operation. Also available with gear box, motor actuators, pneumatic or hydraulic actuators for more difficult services.

2. Grease-jet joint: Installed in prescriptive part accord to the apply and satisfied with ecumenical situations and realize seal in spot with maintenance easily.

3. Body&Bonnet: Split or 3-piece, split body & bonnet for 8″ & small. Disassembles easily for repair or replacement of internal components.

4. Bore: Full bore or reduce bore. Full-bore design provides exceptional flow control.

5. End Connection: A choice of flanged RTJ flanged or butt-welding End for piping flexibility

6. Packing: Standard packing multiple v-teflon packing. combined with live loading, maintains packing compression under high-cycle and service applications. Graphite packing is used for high-temperature situation.

7. DDB: Double Block & Bleed. Trunnion ball valve adopt pre-tightening spring seat, the body cavity is isolated when the ball is in either fully closed or fully opened position, and remains medium inside of body cavity will be excreted by discharge valve.

8. A.S: Anti-statics. A metallic contact is always granted between ball and stem/body to discharge eventual statics build-up during service.

9. F.S: Fire safe, designed to API 607 or BS 6755 to grant their operation suitability in case of fire. Secondary metal-to-metal seal acts as back up if primary seal is destroyed by fire. Valves ordered for compliance with API 607 will be provided with graphite packing and gaskets.

10. Gasket: Standard gasket or double-gasket. Standard gasket made by high-performance rubber seal ring. Double-gasket made by high-performance rubber seal ring and spiral wound graphite.

| Part name | Carton Steel | ASTM Material 18Cr-9Ni-2Mo | Carbon Steel | |

|---|---|---|---|---|

| Body | A216-WCB | A351-CF8M | A352-LCB | |

| Bonnet | A216-WCB | A351-CF8M | A352-LCB | |

| Ball | A182-F304 | A182-F316 | A182-F304 | |

| Stem | A276-304 | A276-316 | A276-304 | |

| Seat | A105+ENP | A182-F316 | A350-LF2+ENP | |

| Seat insert | Glass filled PTFE | |||

| Seat spring | A313-304 | Inconel X-750 | A313-304 | |

| Seat O-ring | NBR | Viton | Viton | |

| Stem O-ring | NBR | Viton | Viton | |

| Bonnet gasket | Graphite+304 | Graphite+316 | Graphite+304 | |

| Bonnet O-ring | NBR | Viton | Viton | |

| Antistatic Spring | A313-304 | A313-316 | A313-304 | |

| Lower cover | A216 WCB | A182-F316 | A182-F304 | |

| Bonnet stud | A193-B7 | A193-B8 | A320-L7 | |

| Bonnet stud nut | A194-2H | A194-8 | A194-4 | |

| Trunnion | A276-304 | A276-316 | A276-304 | |

| Trunnion bearing | 304+PTFE | 316+PTFE | 304+PTFE | |

| Gland flange | A216-WCB | A351-CF8M | A352-LCB | |

| Gland bolt | A193-B7 | A193-B8 | A193-B7 | |

| Stop plate | Carbon steel | Carbon steel+Zn | Carbon steel | |

| Handle | Carbon steel | |||

Technical requirements of trunnion ball valve

Design description

- Full port design

- BB-bolted bonnet, split body

- Three pieces body for 12 & above

- Blow-out proof stem

- Fire safe construction

- Stopper device

- Flanged or butt-welding ends

- Available with worm gear operator

- ISO 5211 mounting pad

- Anti static device

- Trunnion mounted ball type

Applicable standards

Steel ball valves: API 608/API 6D

Steel ball valves: ISO 14313

Fire safe: API 607

Anti static: API 608

Steel valves: ASME B 16.34

Face to face: ASME B 16.10

End flanged: ASME B 16.5

Butt welding ends: ASME B16.25

Inspection and test: API 598/API 6D

Available modifications

Trim change

End connection modification

Packing and gasket change

Operator mounting pad

Hand wheel extension

Pressure equalizing

Anti-static of Fire safe

Client specified coating

Weld end bore change

Oxygen & chlorine cleaning & packing

Designing characteristics of trunnion ball valve

Designing of Anti-blow out stem

The stem is designed separately from the ball with integral T-type round shoulder, retained by gland.

Anti-static Device

Spring plug graphite type anti-static device are applied between the ball, stem, gland flange and body, to keep the electrical continuity between all the metallic components, and ensure the resistance lower than the most severe service requirement.

Trunnion ball valve - Fire Proof Design

External leakage prevention

All the possible external leakage point between stem and gland flange, gland flange and boy, body and adapter are sealed with primary O-ring, then secondary graphite gasket.

When fire burns out the primary o-ring seal, the secondary graphite gasket seal still can prevent the process medium from external leakage.

Internal Leakage Prevention

When fire burns out the primary o-ring seal between the floating seat ring and adapter, also the seal insert between seat ring and ball, the secondary graphite seal between seat ring and adapter, and seat ring & ball metal to metal contact preloaded by spring will minimize the internal process medium leakage.

Emergent Sealant Injection System

Each truunion mounted ball valve of NPS 6″ and larger is equipped with sealant injection located at stem and seats area. The injection is integrated with check valve to provide backup sealing, also a check valve is equipped at front of the sealant injection to avoid blowing out in case wrong operation.

When the soft sealing materials(seat inserts and o-rings) are damaged and leakage happened by fire o other accident, the sealant can be injected the injection fittings.

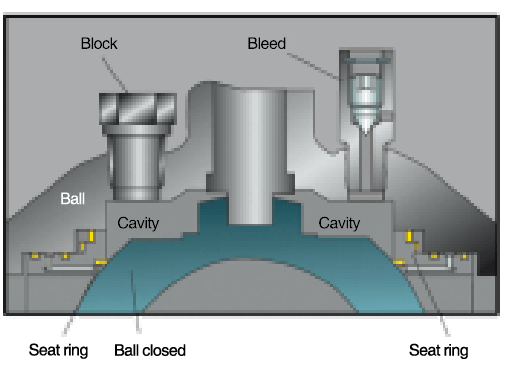

Double Block and Bleed

When the ball is in the closed position, each seat seals off the process medium independently at the same time between the up/down stream and body cavity; it allows bleeding of the trapped cavity pressure trough drain or vent valve.

The double block and bleed function makes it possible to flush the valve under pressure and verify that seats are sealing properly!

Trunnion mounted ball valve - Automatic Bleed of Cavity Pressure

When the cavity pressure (Pc) is less than force of preload of spring (Fs) and the pressure of medium of piping lines (P1), that is △P*D1<Fs, ball and seat preload contact ensuring the sealing.

Otherwise, when the pressure of cavity (Pc) is larger than force of spring and the pressure of medium of piping lines (P1), that is △P*D1>Fs.

The pressure of cavity pushes seat ring, leaving a small space between seat ring and the ball, so that the over load pressure of cavity is automatically drained to the pipelines, recovering to the pressure balance of valve cavity and the pipelines.